Fiona Scarborough

About

Hello,

My name is Fiona! I'm a soft goods designer with an industrial design background and passion for fashion design. I'm most interested in the intersections of sport, self-expression, and utility.Since I earned my degree, I've been going through a period of intense personal growth, building community, and building my involvement within artistic and bicycle-oriented spaces. I've also been practicing and developing shoemaking skills, with which I've been aspiring to create a micro business and pathways into the footwear industry.I've also taught, helped, and learned in various makerspace settings, including Artisans' Asylum and Fabville, a makerspace in Somerville, MA. I enjoy teaching immensely, whether it be around 3D printing, laser-cutting, or bicycle repair.I am currently looking for work in art education,

softgoods design, and the sporting goods industry.You can view my work here

Photo: Mel Taing Photography 2024

Coming soon...

Coming soon...

RAR NAR 2025 - Mechanic Workshop - Photos: Nicole Van Der Wahl Photography

MENACE Tracklocross 2025 - Photos: CAMKINCH

Cycling is culture...

Over the last 5 years, cycling has been a core passion in my life. Through it, I've developed mechanical, athletic, and teaching skills. More importantly, I've developed community and organizing skills, and deeper insight into the products and industry itself. Through cycling, I've met bag makers, frame builders, policy makers, activists, and my closest friends. I've also glimpsed into the eccentricities of how products get made, used, and serviced in the real world. Cycling is a fascinating intersection of athleticism, engineering, and human-scale interactions that have greatly informed me both as a community member, athlete, and designer.

It's hard for me to say exactly why I became so fascinated with shoemaking. I used to modify roller skates, attaching them to sneakers, swapping parts, and hacking them to fit my feet and different sets of wheels.While studying at Massachusetts College of Art & Design, there was a lot of interest among my peers in footwear, but ultimately it was a pretty niche pursuit. I took a few classes in fashion, briefly interned at Reebok, and ultimately when the pandemic hit, I leaned into my hobbies to pass the time.What is fascinating to me about footwear is the problem solving. It's an opaque industry, often even to those who work within it. Old knowledge is hoarded and rarely taught, and larger corporations operate at a scale that is nearly unfathomable. The way that a factory can manufacture a shoe can't often be replicated by a hobbyist. Factories can churn out technical designs with hot-welded non-woven materials, direct-injected soles, and create new molds and tooling for a line of footwear with relative ease.Individual shoemakers compensate for their lesser resources by leaning into older, sometimes more robust techniques, like good-year welted and stitchdown construction, hand-lasting them, and attatching soles with a hammer, anvil, and press.

I love the challenge. I have so much to learn, but I find ways to compensate with my education in CAD, 3D-printing, and pattern drafting. I find myself most excited about customization, and the intersections of size and gender inclusivity in footwear. I believe that as an independent maker without the constraints of minimum order quantities and by creating the products myself, I can one day make footwear for underserved folks, and perhaps inspire other hobbyists.

Below you can see the footwear projects that I've done over the last several years. Most of these projects are older than what will be in my new portfolio, which you can view here. However, I am still proud of this work and the lessons that it all taught me.

The Bubblegum Loafer

In this project, I was principally driven to improve my sneaker making skills. I was inspired by streetwear maximalism, neon colors, and the bold, technical yet experimental look of webbing on shoes.Based on a Vibram Strighton cupsole, I built a low-cut sneaker that has the silhouette of a slip-on flat, the utility of a shoe, and the color and pattern of a bold, streetwear or cyberpunk pattern.

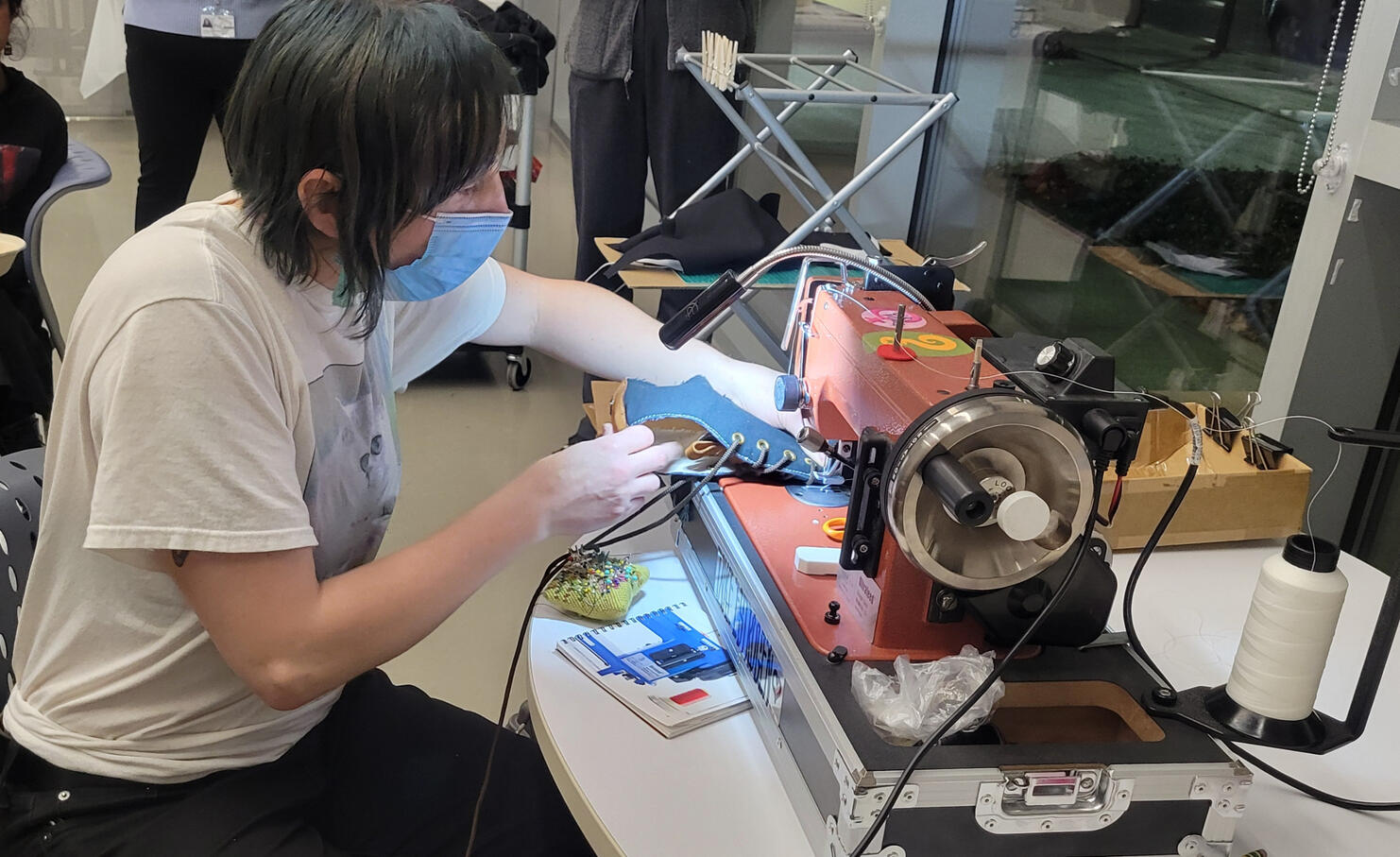

Mentorship Project

In this project, I was asked if I wanted to mentor a young teen who has been trying to develop her fashion design schools for an art school application. At the time, she wanted to learn about footwear design, and I was the only educator that her family knew of with that skillset.For the project, I taught her how to pattern hack, and we deconstructed the pattern for a lace-up canvas shoe, made size-graded patterns, and then re-made the shoe from the ground up.

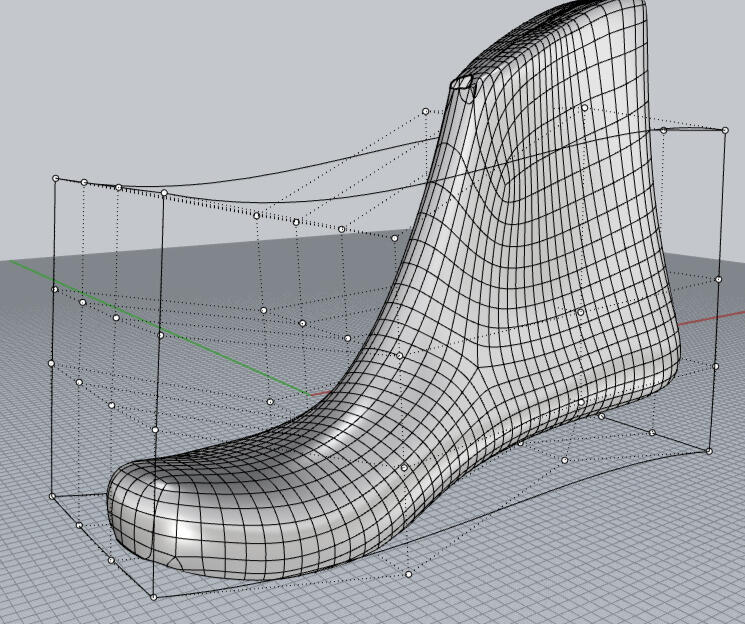

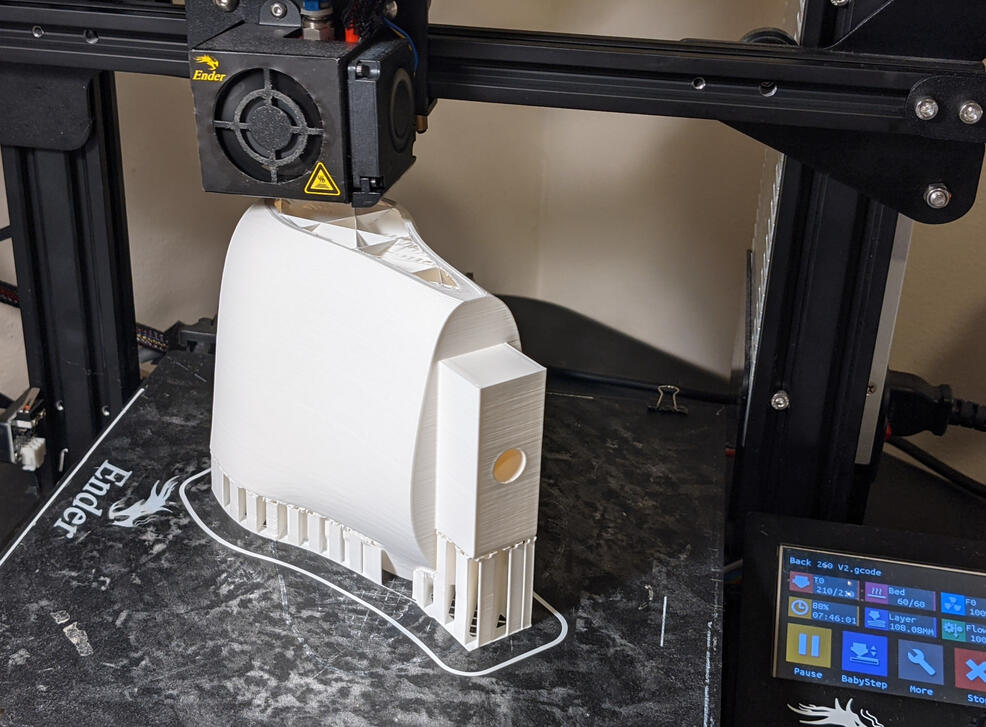

3D Printed Slip-on

This project was a sprint to see how close I could get to a fully 3D printed shoe. Ultimately, I chose to use a liner concept, realizing that a sock might not be sufficient to avoid the blistering effect of rubber on skin, and would add to the potential customizability.

High-Top Triptych

These were an earlier project where I pushed and developed my shoemaking skills to a considerable degree.These were high-tops that I made from the ground up around lasts that I 3D printed, patterns that I made. I hand lasted them myself and stitched them to Vibram Strighton Cupsoles.

First Stitchdown Shoe

For this project, I was most interested in attempting a stitchdown style construction, while blending sneaker aesthetics. This project wasn't a total success, but it taught me a lot of about stitchdown soles, cutting and gluing midsoles, and the unique pattern-making challenges that can emerge in this style of shoe.

Coming soon...